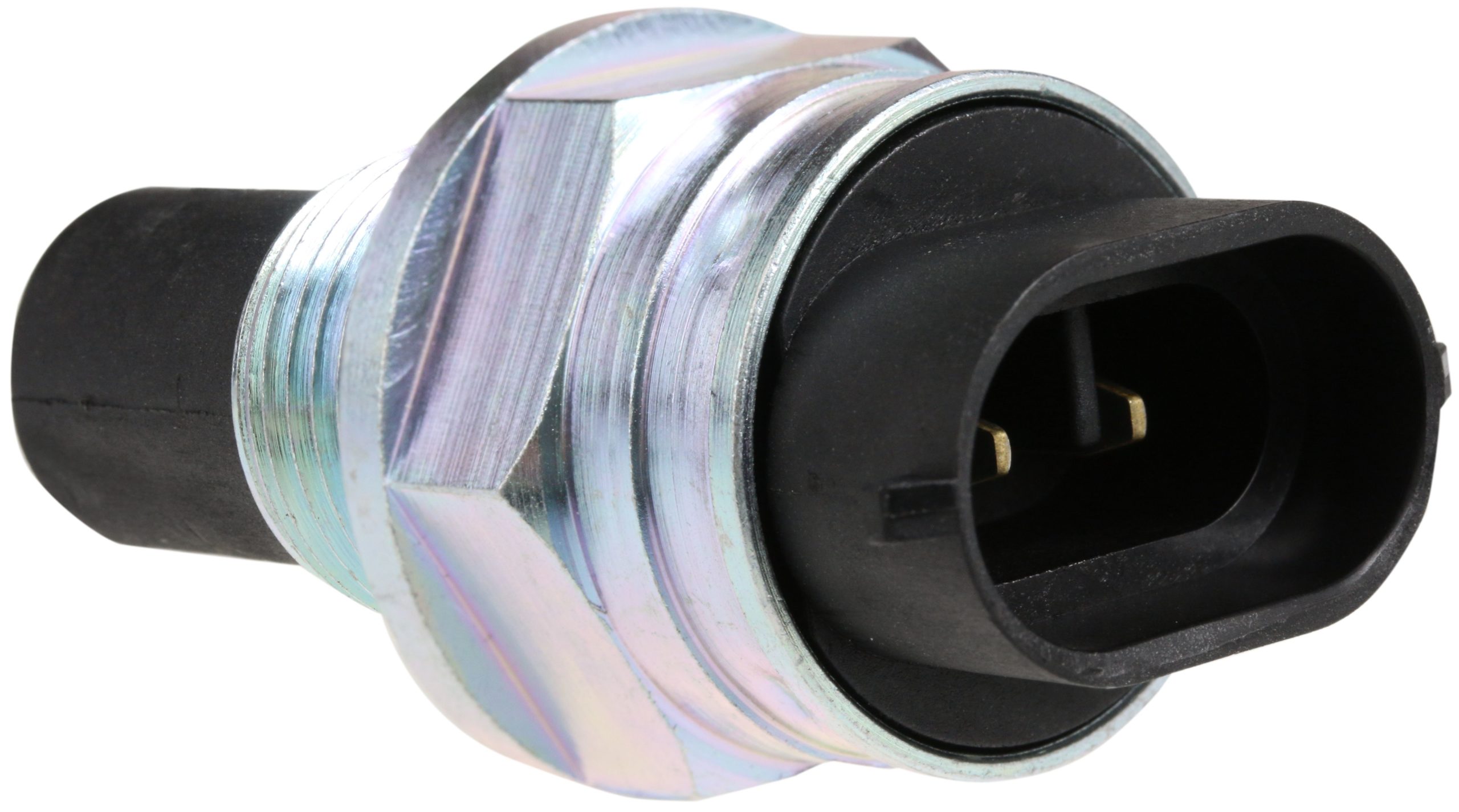

The Exhaust Back Pressure Sensor is an important component in the exhaust system of an internal combustion engine. It monitors the pressure in the exhaust system and provides crucial data to the engine control unit (ECU) for optimizing engine performance and emissions control. Here’s an overview of its features, functions, and benefits:

Key Features:

- Pressure Measurement:

- Measures the back pressure within the exhaust system, typically located upstream of the catalytic converter or diesel particulate filter (DPF).

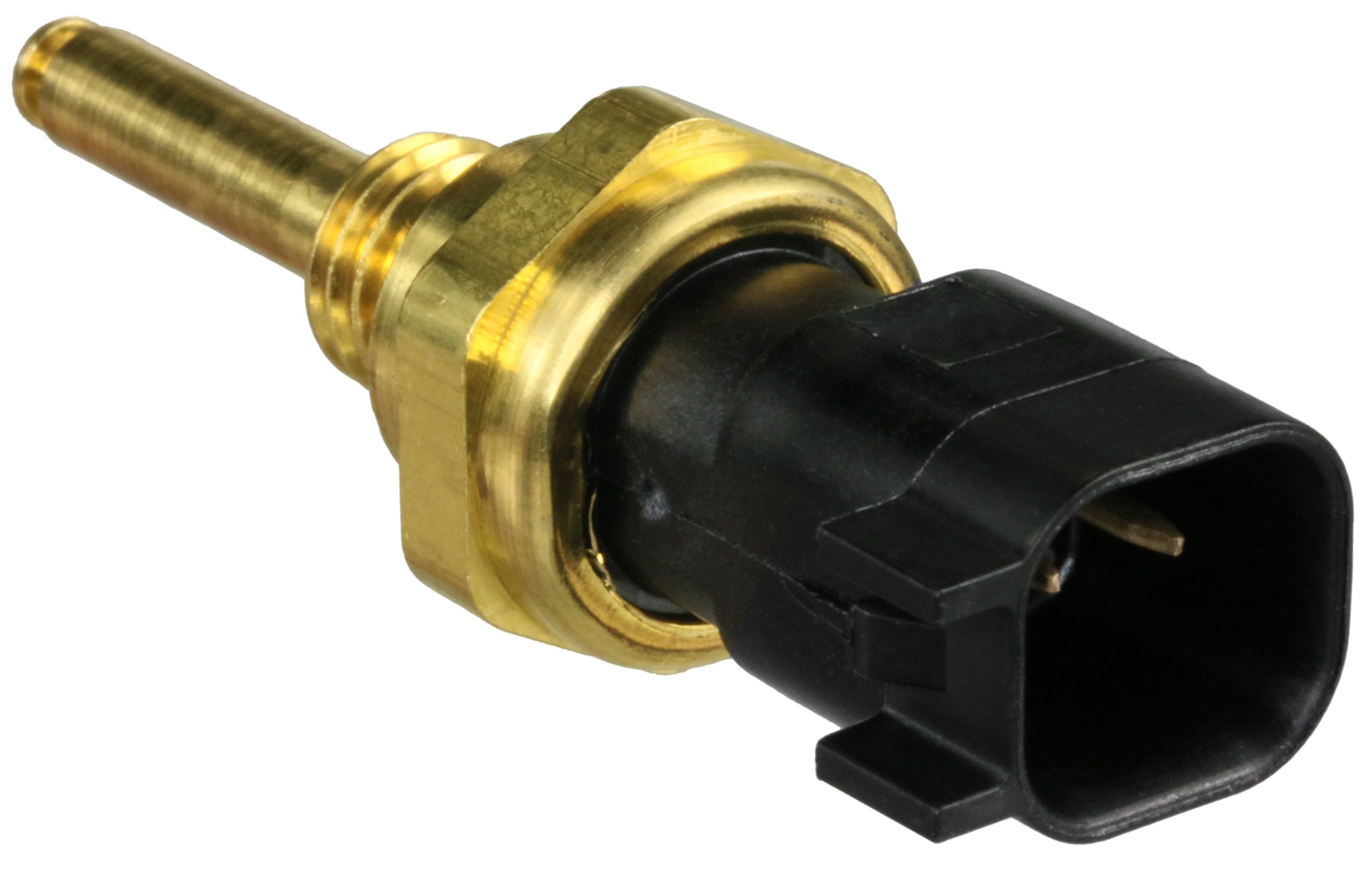

- Durable Construction:

- Built to withstand high temperatures, corrosive exhaust gases, and vibrations within the engine compartment.

- Electrical Output:

- Generates an electrical signal proportional to the exhaust back pressure, which is transmitted to the ECU for analysis.

- Integration:

- Often integrated with other sensors and systems for comprehensive engine management, including turbocharging systems.

Functions:

- Monitoring Exhaust Flow:

- Detects the level of back pressure in the exhaust system, which can indicate restrictions or blockages (e.g., clogged DPF).

- Optimizing Engine Performance:

- Provides data to the ECU for adjusting fuel injection, ignition timing, and boost levels (in turbocharged engines) to maintain optimal performance.

- Emissions Control:

- Helps manage emissions by ensuring the exhaust system is functioning correctly and efficiently, contributing to compliance with environmental regulations.

- Preventing Damage:

- Alerts the ECU to potential issues in the exhaust system, allowing for preventive measures to avoid engine damage due to excessive back pressure.

Benefits:

- Enhanced Performance: By maintaining optimal exhaust flow, the sensor helps improve engine efficiency and power output.

- Improved Fuel Economy: Efficient exhaust management can lead to better fuel combustion, enhancing overall fuel efficiency.

- Reduced Emissions: Effective monitoring of back pressure contributes to lower harmful emissions, aiding in regulatory compliance.

Symptoms of Failure:

- Check Engine Light: A malfunctioning sensor may trigger the check engine light, indicating potential exhaust system issues.

- Poor Engine Performance: Symptoms such as loss of power, rough idling, or decreased acceleration can occur if the sensor fails.

- Increased Emissions: A faulty sensor may lead to elevated exhaust emissions, potentially causing failures during emissions testing.

Replacement:

- Accessibility: The sensor is usually accessible, but replacement may require some disassembly of exhaust components, depending on the vehicle.

- Diagnostic Testing: It’s important to perform diagnostic tests to confirm the sensor’s status before replacement.

Applications:

- Passenger Vehicles: Commonly found in gasoline and diesel engines equipped with advanced emissions control systems.

- Commercial Vehicles: Used in trucks and heavy-duty vehicles where exhaust back pressure monitoring is critical for performance and emissions management.

The Exhaust Back Pressure Sensor is essential for ensuring the efficient operation of the exhaust system and overall engine performance. Regular maintenance and prompt attention to any issues can help maintain optimal vehicle function and compliance with emissions standards.

There are no reviews yet.